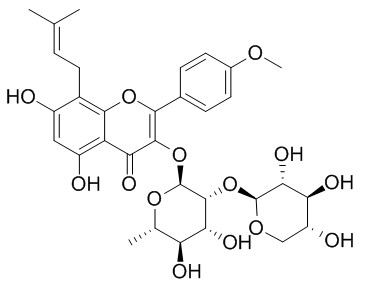

Sagittatoside B

Sagittatoside B is a natural product from Epimedium brevicornu Maxim.

Inquire / Order:

manager@chemfaces.com

Technical Inquiries:

service@chemfaces.com

Tel:

+86-27-84237783

Fax:

+86-27-84254680

Address:

1 Building, No. 83, CheCheng Rd., Wuhan Economic and Technological Development Zone, Wuhan, Hubei 430056, PRC

Providing storage is as stated on the product vial and the vial is kept tightly sealed, the product can be stored for up to

24 months(2-8C).

Wherever possible, you should prepare and use solutions on the same day. However, if you need to make up stock solutions in advance, we recommend that you store the solution as aliquots in tightly sealed vials at -20C. Generally, these will be useable for up to two weeks. Before use, and prior to opening the vial we recommend that you allow your product to equilibrate to room temperature for at least 1 hour.

Need more advice on solubility, usage and handling? Please email to: service@chemfaces.com

The packaging of the product may have turned upside down during transportation, resulting in the natural compounds adhering to the neck or cap of the vial. take the vial out of its packaging and gently shake to let the compounds fall to the bottom of the vial. for liquid products, centrifuge at 200-500 RPM to gather the liquid at the bottom of the vial. try to avoid loss or contamination during handling.

JEJU National University2022, 24032.

Front Pharmacol. 2024, 15:1527494.

Comparative Clinical Pathology 2021, 30:961-971.

Molecules.2017, 22(6)

Eur J Pharmacol.2023, 950:175772.

Acta Biochim Pol.2015, 62(2):253-8

J Clin Med.2019, 8(10):E1664

Pharm Biol.2022, 60(1):2040-2048.

Molecules.2020, 25(17):3783.

J Neuroinflammation.2023, 20(1):268.

Related and Featured Products

Zhongguo Zhong Yao Za Zhi. 2014 Jan;39(2):235-9.

Study on preparation of sagittatoside B with epimedin B converted from cellulase.[Pubmed:

24761637]

METHODS AND RESULTS:

To prepare Sagittatoside B with epimedin B Hydrolyzed from cellulase. With the conversion ratio as the index, the effects of pH value, temperature, reaction time, dosage of enzyme and concentration of substrates on the conversion ratio were detected. L9 (3(4)) orthogonal design was adopted to optimize the preparation process. Hydrolyzed products were identified by MS, 1H-NMR, and 13C-NMR. The results showed that the optimum reaction conditions for the enzymatic hydrolysis were that the temperature was 50 degrees C, the reaction medium was pH 5.6 acetic acid-sodium acetate buffer solution, the concentration of substrates was 20 g x L(-1), the mass ratio between enzyme and substrate was 3: 5, and the relative molecular mass of the reaction product was 646.23. NMR data proved that the product was Sagittatoside B.

CONCLUSIONS:

The process is simple and reliable under mild reaction conditions, thus suitable for industrial production.