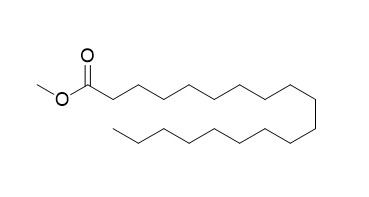

Methyl nonadecanoate

Reference standards.

Inquire / Order:

manager@chemfaces.com

Technical Inquiries:

service@chemfaces.com

Tel:

+86-27-84237783

Fax:

+86-27-84254680

Address:

1 Building, No. 83, CheCheng Rd., Wuhan Economic and Technological Development Zone, Wuhan, Hubei 430056, PRC

Providing storage is as stated on the product vial and the vial is kept tightly sealed, the product can be stored for up to

24 months(2-8C).

Wherever possible, you should prepare and use solutions on the same day. However, if you need to make up stock solutions in advance, we recommend that you store the solution as aliquots in tightly sealed vials at -20C. Generally, these will be useable for up to two weeks. Before use, and prior to opening the vial we recommend that you allow your product to equilibrate to room temperature for at least 1 hour.

Need more advice on solubility, usage and handling? Please email to: service@chemfaces.com

The packaging of the product may have turned upside down during transportation, resulting in the natural compounds adhering to the neck or cap of the vial. take the vial out of its packaging and gently shake to let the compounds fall to the bottom of the vial. for liquid products, centrifuge at 200-500 RPM to gather the liquid at the bottom of the vial. try to avoid loss or contamination during handling.

J Biochem Mol Toxicol.2021, 35(5):e22731.

Int J Cosmet Sci.2022, doi:10.1111/ics.12827.

Evid Based Complement Alternat Med.2015, 2015:165457

Nutraceuticals2022, 2(3),150-161

Int J Mol Sci.2022, 23(10):5468.

Fitoterapia.2024, 175:105958.

Drug Dev Ind Pharm.2024, 50(11):938-951.

Evid Based Complement Alternat Med.2021, 2021:8850744.

Heliyon.2023, 9(6):e16138.

Int Immunopharmacol.2023, 123:110572.

Related and Featured Products

Korean Society for Biotechnology Conference,2017,9:942-943.

Quantification of Fatty Acids Methyl Ester Derived from Dunaliella sp.by Gas Chromatography with New Internal Standards for Precise Analysis.[Reference:

WebLink]

METHODS AND RESULTS:

The most common device used to measure fatty acid methyl ester (FAME) quantification is gas chromatography (GC). GC usually employs internal standard method since injection volume of sample is too small not to differ between each analysis. Methyl heptadecanoate and Methyl nonadecanoate, which are odd carbon numbered fatty acid methyl ester, are commonly used because they don't exist in natural plant lipids. In our study, the biodiesel from Dunaliella sp. contained C16:4, C16:3 FAME which have very similar retention time on gas chromatogram with C17:0, C19:0, the conventional internal standards for biodiesel analysis. To quantify FAME from Dunaliella sp., we used internal standards such as methyl dodecanoate, methyl pentadecanoate and methyl behenate.

CONCLUSIONS:

We determined the response factors of each internal standard and applied them into quantification and compared the results with those of using conventional internal standard, C17:0. Soybean FAME was used to confirm the feasibility of this method, it showed high accuracy.

Talanta, 2017, 174:556-561.

A flow-based procedure exploiting the lab-in-syringe approach for the determination of ester content in biodiesel and diesel/biodiesel blends.[Reference:

WebLink]

The ester content is an important parameter to be monitored in biodiesel for evaluation of the transesterification reaction yield and for assessing the purity of the final product. This is also a relevant quality parameter in diesel/biodiesel blends to avoid frauds, because legislation establishes a minimum amount of biodiesel to be added to diesel. The official method EN14103 requires the addition of an alternative internal standard (Methyl nonadecanoate) for analysis of biodiesel from bovine tallow because the methyl heptadecanoate is found in high amounts in this product.

METHODS AND RESULTS:

In this work, it is proposed a fast, simple, practical, and environmental friendly flow-based spectrophotometric procedure, which exploits the formation of the violet complex between Fe(III) and the hydroxamate generated by the reactions of the alkyl esters with hydroxylamine. All involved steps are carried out inside the syringe pump of a sequential injection analyzer (lab-in-syringe approach). A single phase is attained by using ethanol as mediator solvent between the organic sample and aqueous soluble reagents. Linear responses for biodiesel samples and diesel/biodiesel blends were obtained from 4–99%(v/v) to 2.0–40%(v/v) methyl esters, described by the equations: A = 0.342 + 0.00305C (r = 0.997) and A = 0.174 + 0.00503C (r = 0.999), respectively. The analytical curve can be obtained by in-line dilution of a methyl linoleate stock solution. For biodiesel samples, the coefficient of variation (n = 10), limit of detection (99.7% confidence level), and sampling rate were estimated at 0.8%, 0.36%(v/v), and 15 h−1, respectively, whereas the corresponding values for the blend samples were 0.20%, 0.03%(v/v), and 12 h−1, respectively. The procedure consumes only 860 μg of hydroxylamine, 366 μg of Fe2(SO4)3·H2O, and 2.0 mL ethanol and generates ca. 3.0 mL of residue per determination.

CONCLUSIONS:

The results agreed with those obtained by official methods EN14103/2011 e EN14078, at the 95% confidence level.