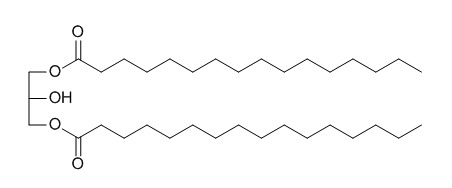

Dipalmitin

Dipalmitin has templating effects on soft palm mid fraction crystals.

Inquire / Order:

manager@chemfaces.com

Technical Inquiries:

service@chemfaces.com

Tel:

+86-27-84237783

Fax:

+86-27-84254680

Address:

1 Building, No. 83, CheCheng Rd., Wuhan Economic and Technological Development Zone, Wuhan, Hubei 430056, PRC

Providing storage is as stated on the product vial and the vial is kept tightly sealed, the product can be stored for up to

24 months(2-8C).

Wherever possible, you should prepare and use solutions on the same day. However, if you need to make up stock solutions in advance, we recommend that you store the solution as aliquots in tightly sealed vials at -20C. Generally, these will be useable for up to two weeks. Before use, and prior to opening the vial we recommend that you allow your product to equilibrate to room temperature for at least 1 hour.

Need more advice on solubility, usage and handling? Please email to: service@chemfaces.com

The packaging of the product may have turned upside down during transportation, resulting in the natural compounds adhering to the neck or cap of the vial. take the vial out of its packaging and gently shake to let the compounds fall to the bottom of the vial. for liquid products, centrifuge at 200-500 RPM to gather the liquid at the bottom of the vial. try to avoid loss or contamination during handling.

iScience.2023, 26(9):107602.

Srinagarind Medical Journal2019, 34(1)

J of Dentistry & Oral Health2019, 2641-1962

Horticulturae2020, 6(4),76.

Food Science and Biotechnology2023, 2023:1007

Kor.J.Herbol.2024, 39(3):23-35

J Cancer.2019, 10(23):5843-5851

Molecules.2017, 22(2)

Nat Commun.2019, 10(1):2745

Plants (Basel).2021, 10(12):2795.

Related and Featured Products

Biophys J. 1997 Nov;73(5):2603-14.

Effects of dipalmitoylglycerol and fatty acids on membrane structure and protein kinase C activity.[Pubmed:

9370455]

METHODS AND RESULTS:

The individual and combined effects of the saturated diacylglycerol (DAG) Dipalmitin (DP) and saturated or polyunsaturated unesterified fatty acids (PUFAs) on both the structure of phosphatidylcholine/phosphatidylserine (PC/PS; 4:1 mol/mol) bilayers and on protein kinase C (PKC) activity were studied using 2H nuclear magnetic resonance (NMR) and enzyme activity assays. In the absence of DP, PUFAs only slightly activated PKC whereas palmitic acid had no effect. In the absence of fatty acids, DP induced lateral phase separation of the bilayer into liquid-crystalline and gel phases. Under these conditions virtually all DP was sequestered into the gel phase and no activation of PKC was observed. The addition of polyunsaturated arachidonic or docosahexaenoic acids to the DP-containing bilayers significantly increased the relative amounts of DP and other lipid components in the liquid-crystalline phase, correlating with a dramatic increase in PKC activity. Furthermore, the effect was greater with PS, resulting in an enrichment of PS in the liquid-crystalline domains. In the presence of DP, palmitic acid did not decrease the amount of gel phase lipid and had no effect on PKC activity.

CONCLUSIONS:

The results explain the observed lack of PKC-activating capacity of long-chain saturated DAGs as due to the sequestration of DAG into gel domains wherein it is complexed with phospholipids and thus not available for the required interaction with the enzyme.

International Journal of Food Properties, 19 Apr 2017

Templating effects of dipalmitin on soft palm mid fraction crystals[Reference:

WebLink]

The crystallization of lipids has important implications for the industrial processing of food products, such as chocolates, margarines, spreads, confectionery, as well as bakery and dairy products.

METHODS AND RESULTS:

Thus, blends of soft palm mid fraction (PMF) and Dipalmitin (PP) containing PP of 0.5g/100g and 1.0g/100g were investigated under stabilization time and conditions for controlling and improving the crystallization step of fat during fat modulation. Crystallization results showed by the reduction in the Avrami parameters tsfc, t1/2 and k, that the addition of PP accelerated the crystallization process of PMF. Changes in the crystals morphology observed by polarized light microscopy gave a higher crystallized area and reduced crystals size in the microstructure of the PMF, which also verified by the increase in melting point and SFC. The addition of PP caused changes in the arrangement of the PMF triacylglycerols (TAGs), by stabilizing the β′stable polymorphic form, thereafter stabilizing the melting profile, and consistency of the PMF over time.

CONCLUSIONS:

These results have interesting implications in the fat and oil industry as it allows for the marketing of products with improved crystallization properties and stabilization of more stable polymorphic forms, expanding the range of application of slow crystallizing fats.